The EEPROM (ELECTRICALLY ERASABLE PROGRAMMABLE READ ONLY MEMORY) is a very useful memory which can be used for storing data. The data storing and retrieving from any EEPROM memory is very simple compared to other kind of memories. As the name suggest the memory is electrically programmable and hence the data will be sustained in the memory until it is electrically erased or reprogrammed.

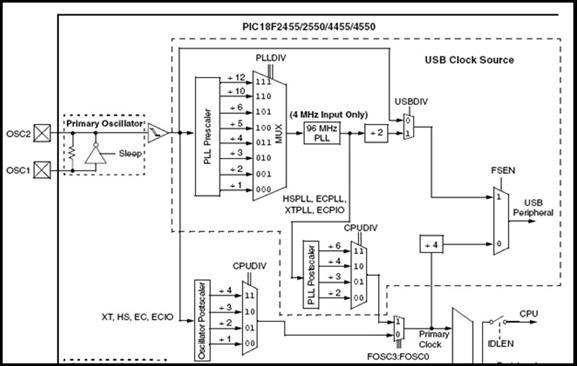

There are lots of EEPROM chips available most of them are easy to interface with a microcontroller. It would be even better if the microcontroller itself has a built-in EEPROM. The microcontroller used in this project is PIC18F4550 and it also has an inbuilt EEPROM memory other than the flash memory. The data can be easily stored into or retrieve using simple codes.

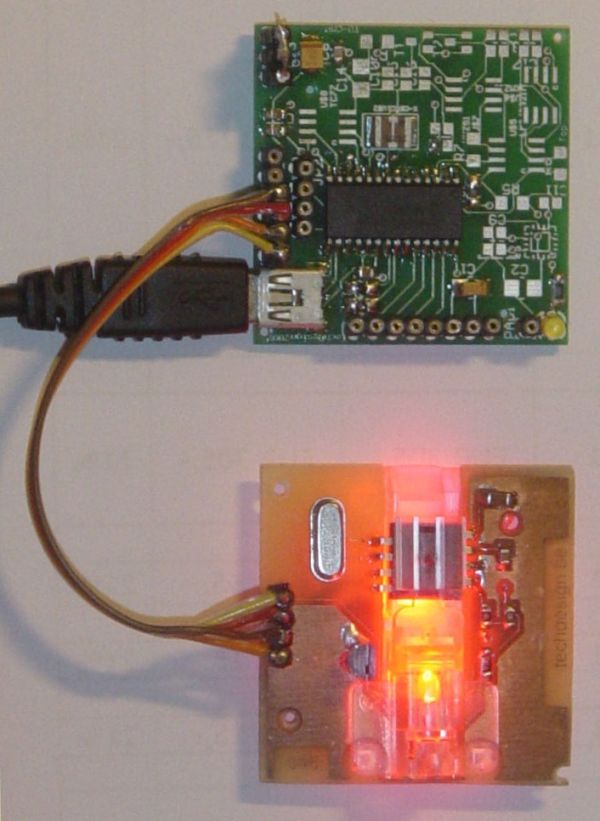

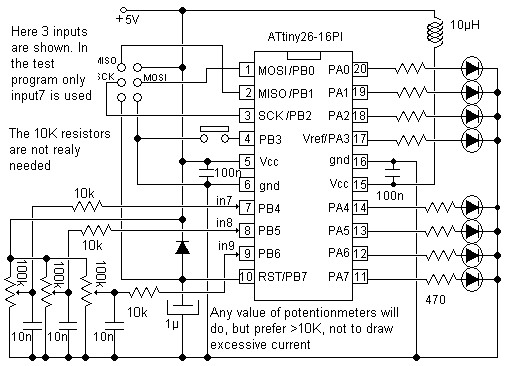

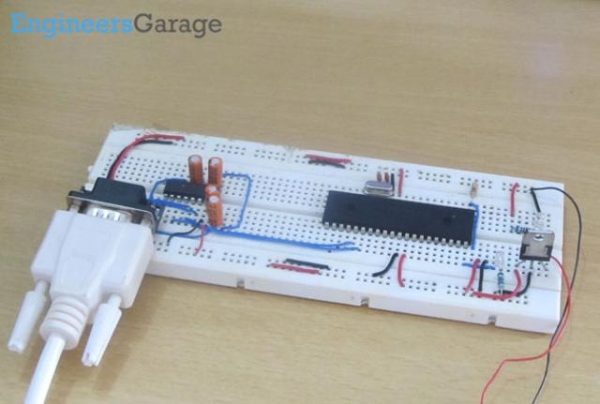

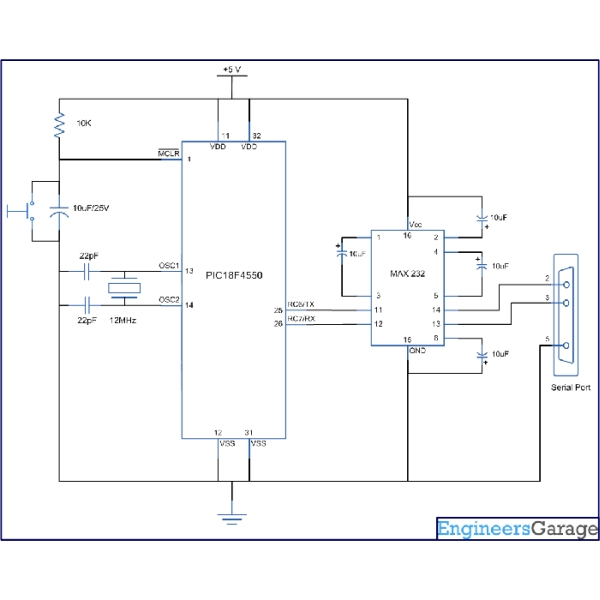

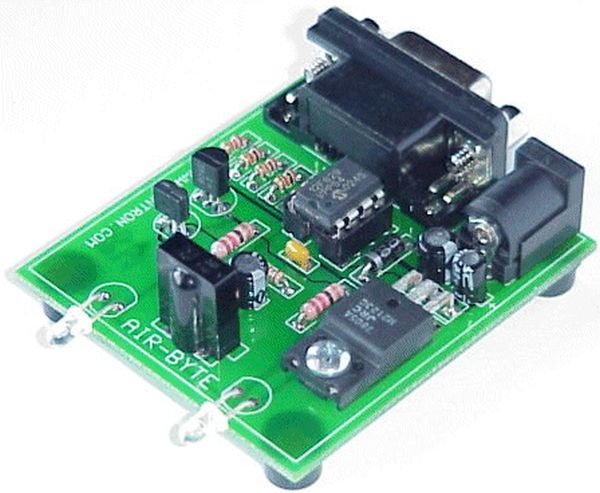

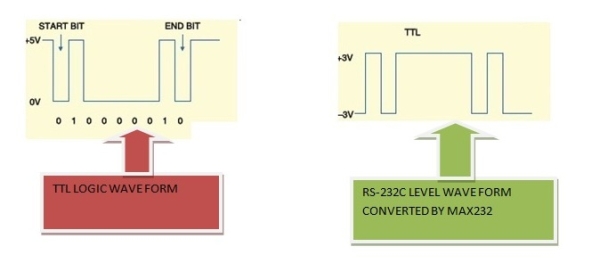

![How to use inbuilt EEPROM of PIC18F4550 Microcontroller]() The project mainly has two parts, a serial communication part and EEPROM accessing part. The data which should be written into the EEPROM is received from the serial port. The internal hardware module USART is used for this purpose. The data which is read from the EEPROM is also send back to the serial port using the same hardware module.

The project mainly has two parts, a serial communication part and EEPROM accessing part. The data which should be written into the EEPROM is received from the serial port. The internal hardware module USART is used for this purpose. The data which is read from the EEPROM is also send back to the serial port using the same hardware module.

Hence two internal modules of the PIC18F4550 are used in this project namely EEPROM and USART. These hardware modules can be accessed and controller by simply writing into or reading from their corresponding registers.

The important control registers associated with the USART and their details are given below:

TXSTA: TRANSMIT STATUS AND CONTROL REGISTER

This register has the bits which controls the serial transmission features like enable or disable the transmission, whether it should be synchronous asynchronous etc.

For a simple asynchronous serial transmission only two bits are significant, which are TXEN and SYNC

TXEN is the transmission enable/disable bit and SYNC sets the synchronous/asynchronous mode.

TXEN: Transmit Enable

1 = Transmit enabled

0 = Transmit disabled

SYNC: EUSART Mode Select bit

1 = Synchronous mode

0 = Asynchronous mode

RCSTA: RECEIVE STATUS AND CONTROL REGISTER

This register has the bits which controls the serial reception features like enable/disable the serial port, reception should be 8 bit or 9 bit, whether it should be synchronous asynchronous, enable/disable continuous reception etc.

For a simple asynchronous serial reception the significant bits are SPEN, RX9 and CREN.

SPEN: Serial Port Enable bit

1 = Serial port enabled

0 = Serial port disabled

RX9: 9-Bit Receive Enable bit

1 = Selects 9-bit reception

0 = Selects 8-bit reception

CREN: Continuous Receive Enable bit

1 = Enables receiver

0 = Disables receiver

SPBRG: EUSART BAUD RATE GENERATOR REGISTER

This is a 16 bit register into which the value corresponding to the required baud-rate can be written into. The value according to a particular baud-rate can be calculated from the CPU clock frequency according to the following equation;

SPBRG = ((FOSC/Desired Baud Rate)/64) – 1

Where; FOSC is the CPU clock frequency

#include <p18f4550.h>

//======================= chip config ===================//

#pragma config PLLDIV = 1

#pragma config CPUDIV = OSC1_PLL2

#pragma config FOSC = INTOSC_HS

#pragma config USBDIV = 1

#pragma config IESO = OFF

#pragma config PWRT = OFF

#pragma config BOR = OFF

#pragma config VREGEN = OFF

#pragma config WDT = OFF

#pragma config WDTPS = 32768

#pragma config CCP2MX = ON

#pragma config PBADEN = OFF

#pragma config LPT1OSC = OFF

#pragma config MCLRE = ON

#pragma config STVREN = ON

#pragma config LVP = OFF

#pragma config ICPRT = OFF

#pragma config XINST = OFF

#pragma config DEBUG = OFF

#pragma config WRTD = OFF

//======================= chip config ===================//

void tx_data(unsigned char data);

unsigned char rx_data ( void );

void delay_ms ( int delay );

void eeprom_write ( unsigned char data, int address );

unsigned char eeprom_read ( int address );

unsigned char read_address = 0;

unsigned char write_address = 0;

unsigned char write_data;

unsigned char read_data;

unsigned int i=0;

#define FREQ 8000000 // CPU Frequency

#define baud 9600

#define spbrg_value (((FREQ/64)/baud)-1) // Refer to the formula for Baud rate calculation in Description tab

void main(){OSCCON = 0x72; // set CPU Frequency as 8 MHz

TRISB = 0x00; // Set PORTB as output PORT

LATB = 0xFF; // Set PORTB high initially (All LEDs on)

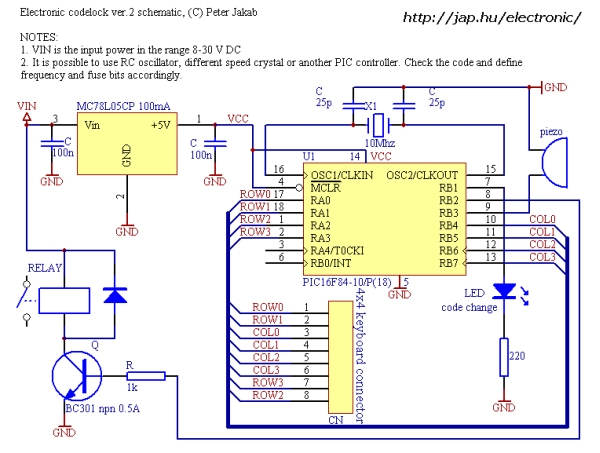

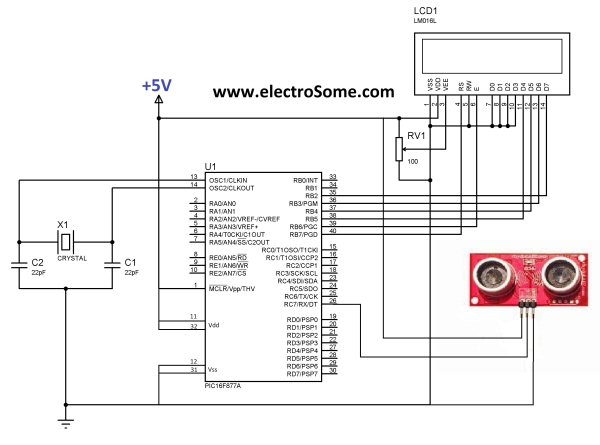

![How to use inbuilt EEPROM of PIC18F4550 Microcontroller Schematic]()

SPBRG = spbrg_value; // Fill the SPBRG register to set the Baud Rate

RCSTA |= 0x80; // To activate Serial port (TX and RX pins)

TXSTA |= 0x20; // To enable transmission

RCSTA |= 0x10; // To enable continuous reception

while(1)

{ write_data = rx_data (); // Receive data from PC

tx_data ( write_data ); // Transmit the same data back to PC

if ( write_data == 0x1A )

{ delay_ms ( 100 );

for ( read_address = 0; read_address < 256; read_address ++ ) // read out all the data from 0 to 256

{ read_data = eeprom_read ( read_address );

tx_data ( read_data ); // Transmit the same data back to PC

delay_ms ( 200 ); }

while ( 1 ); }

else { eeprom_write ( write_data, write_address ); // store the received data into the eeprom

write_address ++; } }}

void eeprom_write ( unsigned char data, int address )

{

EEADR = address; // wite the required address

EEDATA = data; // write the data

EECON1 &= 0x3F; // EEPGD = 0, CFGS = 0, all other bits are kept unchanged

EECON1 |= 0x04; // WREN = 1, all other bits are kept unchanged

INTCONbits.GIE = 0; // disable all interrupt

EECON2 = 0x55; // should write this value before initializing write

EECON2 = 0xAA; // should write this value before initializing write

EECON1 |= 0x02; // WR = 1, all other bits are kept unchanged

INTCONbits.GIE = 1; // enable interrupts

while ( EECON1 & 0x20 ); // wait till WR becomes 0

EECON1 &= 0xFB; // WREN = 0, all other bits are kept unchanged}

The post How to use inbuilt EEPROM of PIC18F4550 Microcontroller appeared first on PIC Microcontroller.